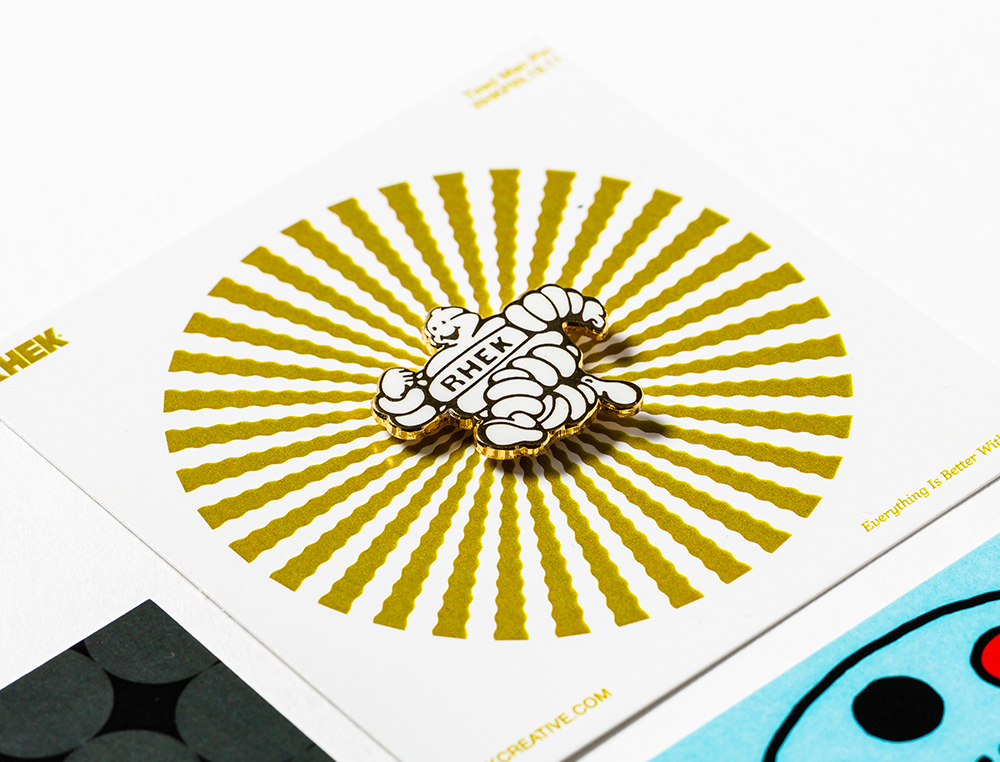

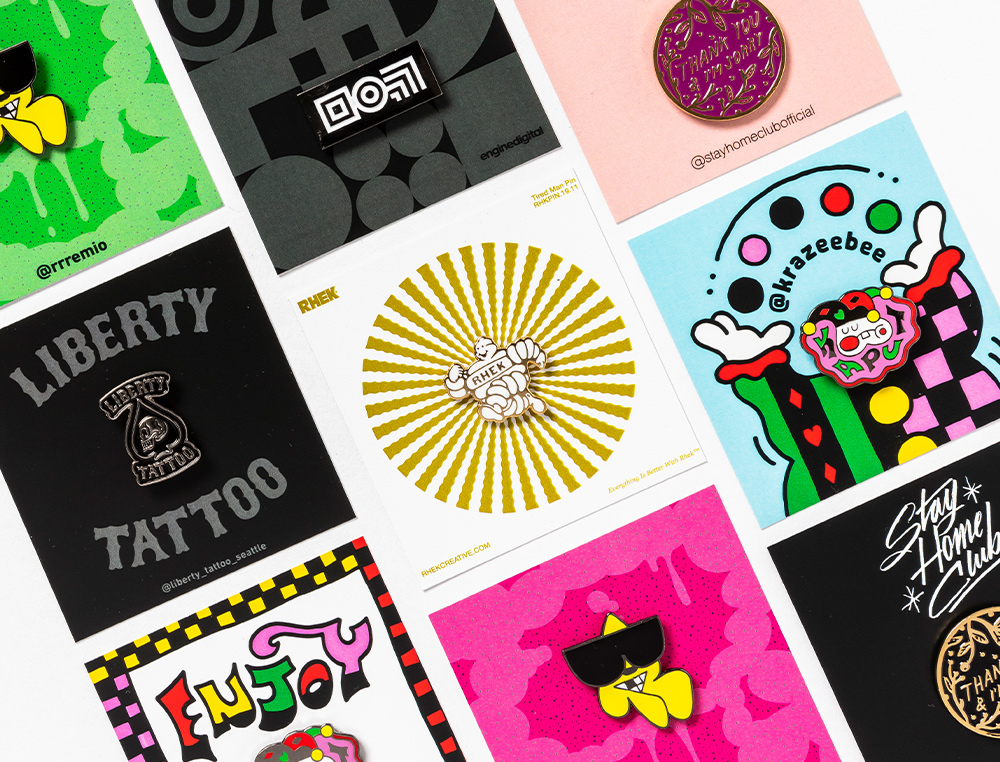

Packaging

Let us package & protect your enamel pins straight out the gate! Custom packaging makes your enamel pins extra attractive & retail ready for your

online shop or market place. Pins are pinned to a 3 x 3" full colour, heavy 16pt card and placed in a resealable poly bag, adding extra protection for those

hand-to-hand exchanges.

Download and design your own custom full colour backing card and we'll package it!

Download and design your own custom full colour backing card and we'll package it!

Why Choose Our Pins?

Superior craftsmanship

Consistent Colour Matching

Reliable Timelines

Steadfast Communication

Request a Quote

Let us know the details of your project & we'll provide a detailed quote & timeline within 1 Business day.

Common Questions

How long will it take for me to receive my pins?

From the time artwork is received and approved, production and delivery is typically 4-6 weeks.

How do I get started?

Have your artwork files ready to upload, fill out our request a quote form to the best of your ability.

If you are unsure of which metal type to choose, we'd be happy to advise the best option based on

your artwork. We cannot generate a quote without reviewing artwork.

How should I save and send artwork?

We recommend creating vector artwork in Adobe Illustrator. Convert any text to outlines, save as

an AI, EPS or PDF and provide Pantone numbers for exact colour matching.

After you fill out our request a quote and upload your files, please provide any additional information about your project in the special instruction field.

After you fill out our request a quote and upload your files, please provide any additional information about your project in the special instruction field.

What is the minimum amount of pins I can order?

Minimum order start at 100 pins per design.

What is the difference between Soft Enamel pins & Hard Enamel Pins?

Soft enamel pins start out as a shaped piece of base metal and are struck with a die to create recessed areas.

These recessed areas are where the color enamel is applied. The raised areas act as the outline of your design,

separating the colors from one another. Once dry, a layer of enamel paint is applied to the recessed areas, which

sit lower than the raised area, creating a ridged finish. Custom soft enamel pins are cheaper to produce than hard

enamel pins and offer a budget-friendly option, popular for fundraising events and promotional items.

Hard enamel pins start out as a shaped piece of base metal, and are also struck with a die to create recessed areas. Again, the recessed areas are where the color enamel is applied and the raised areas act as the outline of your design, separating the colors from one another. However, enamel paint is applied in multiple layers within the recessed areas of the pin until the paint sits level with the raised areas, resulting in the surface becoming smooth and flat. The pin is dried at a high temperature and polished for a high quality, hard wearing shiny finish.

Hard enamel pins start out as a shaped piece of base metal, and are also struck with a die to create recessed areas. Again, the recessed areas are where the color enamel is applied and the raised areas act as the outline of your design, separating the colors from one another. However, enamel paint is applied in multiple layers within the recessed areas of the pin until the paint sits level with the raised areas, resulting in the surface becoming smooth and flat. The pin is dried at a high temperature and polished for a high quality, hard wearing shiny finish.